Products

D110PKUW

The D110PKU lightweight, portable air compressor is the perfect fit for private contractors and rental stores alike.

D185PKR

Internally the D185PKR is powered by a 48.8 hp Tier 4 Final Kohler engine and boasts a Sullivan-Palatek factory made 108 mm rotary screw air end at its core.

D185PDKR

Compact in design, the unit is also equipped with a foldable drawbar to minimize its overall footprint in shipping and storage.

D185PIZP

Its compact design includes a foldable drawbar to minimize space during shipping and storage.

D185PIZ4

Powered by a 49 hp diesel engine, this design has two stage air filter and large 30 gallon fuel tank for full shift duties.

D210PHKR

The D210PHKR portable air compressor delivers 210 cfm with dual operating pressures of 100 or 150 psi.

D260PDKR

The D260PDKR is a dual pressure/dual capacity portable air compressor, capable of delivering 260 cfm at 100 psi or 185 cfm at 150 psi.

D300PD2KR

The D300PD2KR is a dual pressure/dual capacity portable air compressor, capable of delivering 300 cfm at 100 psi or 230 cfm at 150 psi.

D375PHKR

Our D375PHKR portable compressor is a versatile unit, delivering 375 cfm at 150 psi.

D750 & 900 SERIES

With variable operating pressures of 100 or 150 psig, these compressors offer flexibility to meet different project requirements.

D1150PXHD1CU4

This compressor provides immense power for drilling, sandblasting, backup power for plants and refineries, and a wide variety of rental applications.

D1600PH1CU4

This compressor provides tremendous power for drilling, sandblasting, backup air power for plants and refineries, and a wide variety of applications.

OFFSHORE PORTABLE SERIES

To ensure utmost protection, they feature powder-coated Galvanneal enclosures, supported by galvanized railings, 4-point lifts, and skids.

UTILITY MOUNT SERIES

The Utility Mount Air Compressors provide air flow rates of 185, 210, and 260 cfm, along with pressure options ranging from 100 to 150 psi.

Products

SO Series (Oil Free)

Its technologically mature and maintenance-friendly design makes the production of oil-free compressed air safe, reliable and economical.

EO Series

A low-maintenance models perfect for environments requiring high-quality, oil-free compressed air close to the workplace – for example in hospitals and laboratories.

DS-2 Refrigerated Air Dryers

Thanks to the fully integrated design of its highly efficient heat exchanger, the DS-2 N upstages all other re frigerant dryers in terms of energy efficiency with significantly reduced refrigerant consumption

Duotherm

The external BOGE DUOTHERM heat recovery system saves you real money because it can recover up to approx. 94 percent of the input energy used in compression in the form of heat.

Heatless Desiccant Dryers

F Series Filters

The BOGE compressed air filter range features market leading performance, which saves valuable energy dollars and ensures your system is protected from contaminants.

Z Series Water Separator

The BOGE water separator is designed to ensure efficient removal of bulk liquid from the compressed air system.

CC-2 Oil Water Separator

the new BOGE CC-2 oil-water separator complies reliably with the legal threshold values for hydrocarbons when processing “dischargeable” water from condensate via different filter stages, irrespective of which oil you use.

CCD Zero Loss Drain

BOGE’s innovative CCD condensate drains come into play wherever condensate occurs – in filters, dryers or cyclone separators.

Leak Stop

The smartest most cost effective way of putting a stop to compressed air system losses is the BOGE leak stop. A totally maintenance free, flexible programmable system capable of saving a significant amount of money.

SRHV Series Booster

Irrespective of the maximum compression ratio, not only can any final pressure required between 232 and 580 psig be produced – the primary pressure can also be selected anywhere between 29 and 145.

Custom Compressor Packages

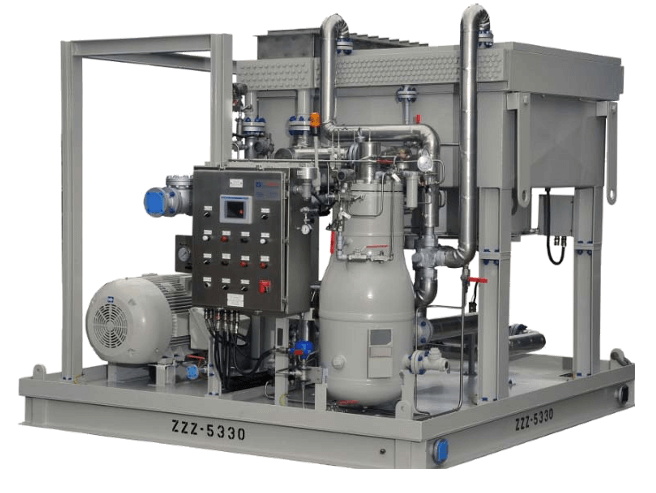

3 x 50% Air Compressor

3 x 50% Air Compressor

Capacity: 815 cfm (1290Nm3/h)

Pressure: 150 psig (10.3barg)

Type: Rotary Screw Oil Flooded

Location: Offshore – Gulf of Mexico

Area Class: Class I, Div. 2

Application: Platform Instrument Air

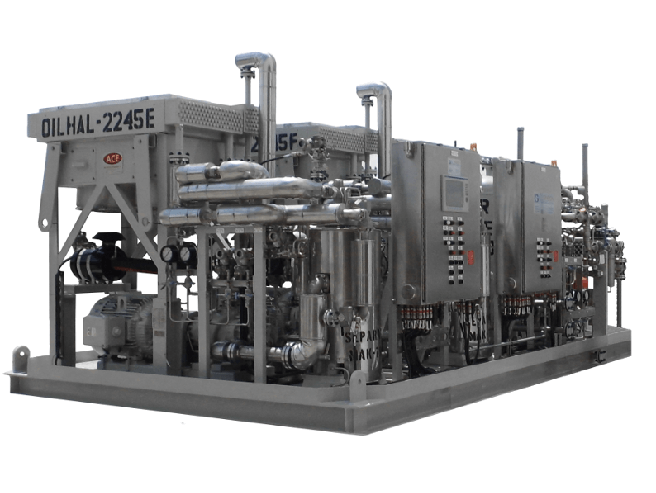

2 x 100% Air Compressor

Capacity: 300 cfm (475Nm3/h)

Pressure: 175 psig (12barg)

Type: Rotary Screw Oil Flooded

Location: Offshore – Africa

Area Class: Class I, Div. 2

Application: Platform Instrument Air

2 x 100% Air Compressor

2 x 100% Air Compressor

Capacity: 140 cfm(221Nm3/h)

Pressure: 175 psig (12barg)

Type: Rotary Screw Oil Flooded

Location: Offshore – Gulf of Mexico

Area Class: Class I, Div. 2

Application: Platform Instrument Air

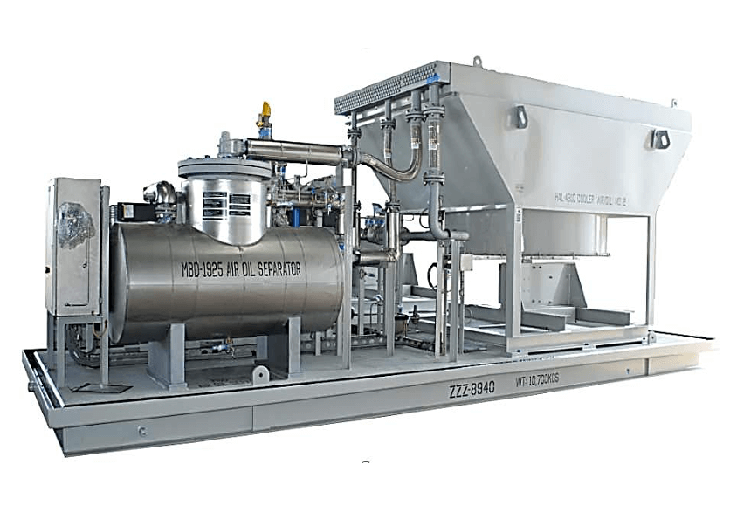

Offshore Air Compression

Capacity: 800 cfm (1266Nm3/h)

Pressure: 175 psig (12barg)

Type: Rotary Screw Oil Flooded

Location: Offshore – Israel

Area Class: IEC Ex D

Application: Platform Instrument Air

Portable Air Compression

Capacity: 1800 cfm (2849Nm3/h)

Pressure: 350 psig (24barg)

Type: Rotary Screw Oil Flooded

Location: Worldwide

Area Class: Class 1 Div. 2

Certification: DNV 2.7-1

Application: Nitrogen Generation

Portable Air Compression

Capacity: 1500 cfm (2375Nm3/h)

Pressure: 500 psig (34barg)

Type: Rotary Screw Oil Flooded

Location: Worldwide

Area Class: ATEX Zone 2

Certification: DNV 2.7-1

Application: Nitrogen Generation

Oil Free Compressor

Capacity: 299 cfm (473Nm3/h)

Pressure: 145 psig (10barg)

Type: Rotary Screw Oil Free

Location: Onshore – Iraq

Area Class: Non Hazardous

Driver: Electric Motor

Application: Instrument Air and Nitrogen Generation

Portable Booster Compressor

Capacity: 1500 scfm (2375Nm3/h)

Pressure: 5000 psig (345barg)

Type: Reciprocating Oil Lubricated

Location: Worldwide

Area Class: Class 1 Div. 2

Certification: DNV 2.7-1

Driver: Electric Motor

Application: Nitrogen Injection

Portable Booster Compressor

Capacity: 2000 scfm (3166Nm3/h)

Pressure: 5000 psig (345barg)

Type: Reciprocating Oil Lubricated

Location: Worldwide

Area Class: ATEX Zone 2

Certification: DNV 2.7-1

Driver: Diesel Engine

Application: Underbalance Drilling

Portable Booster Compressor

Capacity: 3000 scfm (4749Nm3/h)

Pressure: 5000 psig (345barg) Type: Reciprocating Oil Lubricated

Location: Worldwide

Area Class: ATEX Zone 2

Certification: DNV 2.7-1

Driver: Diesel Engine

Application: Oil Field Services

Offshore Booster Compressor

Capacity: 20 scfm (32Nm3/h)

Pressure: 2200 psig (150barg)

Type: Reciprocating Oil Free

Location: Onshore – Indonesia

Area Class: Non Hazardous

Driver: Electric Motor

Application: Plant High Pressure Nitrogen

Offshore Booster Compressor

Capacity: 17scfm (27Nm3/h)

Pressure: 3400 psig (234barg)

Type: Reciprocating Oil Free

Location: Offshore- Gulf of Mexico

Area Class: Class I Div. 2

Driver: Electric Motor

Application: Platform High Pressure Nitrogen

Offshore Booster Compressor

Capacity: 40scfm (63Nm3/h)

Pressure: 2700 psig (186barg)

Type: Reciprocating Oil Free

Location: Offshore- Africa

Area Class: Class I Div. 2

Driver: Electric Motor

Application: Platform High Pressure Nitrogen

Oil Free Reciprocating Type

GE CFH 62 Gas Compressor Package

GENERON® Gas Compressor Package, utilizing a GE-CFH62 Gas Compressor 2350 scfm (3720 Nm3/hr) Capacity @ 1100 psig (76 barg) Discharge Pressure√

N2 Booster Compressor

Capacity: 966scfm (1530Nm3/h)

Pressure: 5000 psig (345barg)

Location: Onshore – USA

Area Class: Non Hazardous Area

NG Compression Package

Capacity: 514scfm (813Nm3/h)

Pressure: 750psig (52barg)

Location: Onshore – USA

Area Class: Class 1 Div. 2

NG Compression Package

Capacity: 417scfm (660Nm3/h)

Pressure: 1000psig (69barg)

Location: Onshore – USA

Area Class: Class 1 Div. 2

VRU Compression Package

Capacity: 1042scfm (1621Nm3/h)

Pressure: 60psig (4barg)

Location: Offshore – Nigeria

Area Class: Class 1 Div. 2